Any design of a layout that is used on custom parchment paper needs attention to detail and effective planning. Designs should carry the idea of aesthetics as well as functional space so as to present the branding in the best way possible. The knowledge of limitations and strengths of material is very important when designing the most favorable things. Maximizing layout prevents wasting of space, as well as makes the product look professional. Every design component should organically appear in the printable area that is provided. Appropriate layout will influence perception and ease of use. This guide highlights the important steps to come up with the perfect layouts of parchment paper.

Material Understanding

It is a crucial component to know the functions of custom parchment paper before setting up any kind of design work. The finish and the texture affect the appearance of the colors after printing them. Parchment paper is slightly translucent, and this will interfere with ink absorption and clarity. Designing with such material implies using colors that are bright and do not bleed. The margins have to be well thought out so as not to amputate vital pieces of the design. Before using parchment sheets, it is advisable to test the proofs. Such tests provide the actual appearance of the design in practice and allow for optimizing the aspects.

Design Placement

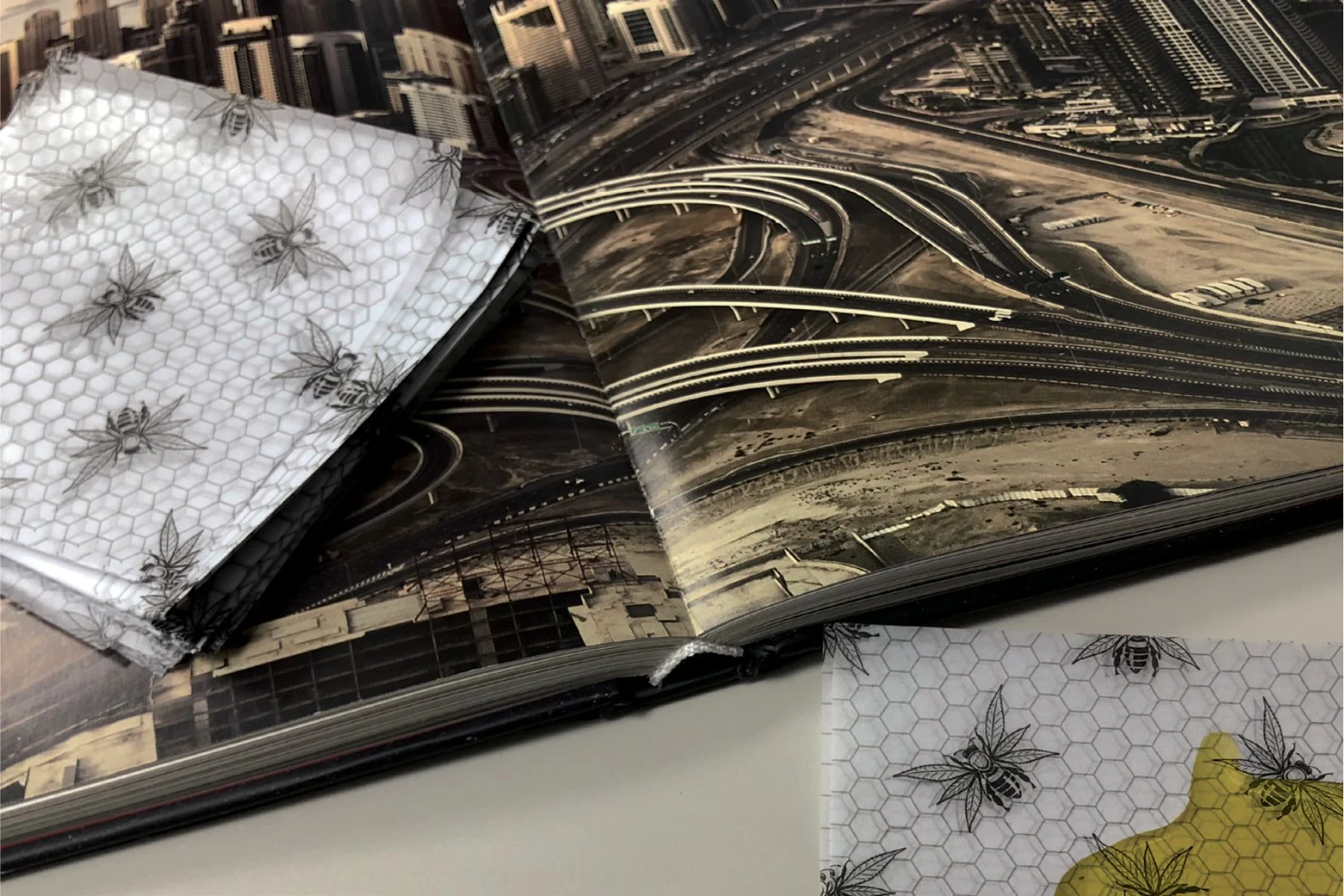

Positioning is everything in a design, even when it concerns custom printed parchment paper. The details that are to be used, especially logos and patterns, must be placed where they can be seen best. Central or upper parts are normally better noticed and do not have folding or creasing areas. Graphics that are important should also be placed none too soon unless risks of cutting the graphics are involved. The space between the design elements balances and makes things readable. A correct alignment between the layout makes it professional and striking to look at. The placement decisions can be simplified and consistent through the use of grid systems.

Color Selection

The selection of suitable colors will affect the overall appearance of a personalised parchment paper. Parchment paper may be off white, so there should be a good contrast in color to be noticeable. Avoid the very light colors that may blend into the background. Choose daring and intense colors that are still visible when printed. The colors also vary based on the type of ink used, so one will have to coordinate with the printer. The use of sheer tones to give a layer adds depth on top of the overpowering design. A clean color scheme makes it easier to read and creates brand awareness.

Typography Focus

Typography: This is where the serious type selection comes in when the designer is doing custom paper. The fonts should be easy to follow and understand in different sizes. Use similar font sizes and weights to prevent cluttering. White space between the letters, as well as line spacing, is also contributory to balance and comfort to the eyes of the viewer. Fonts should be checked, but never on screen. This will make sure the text comes out sharp and clear and will not blur.

Branding Integration

Successful branding embedding turns custom curtains on the shelves in the form of parchment paper sheets into a marketing weapon. The tags, the slogans, and the corporate colours need to be aligned in the layout. The paper is an extension of brand identity. Due to consistency with other elements of packaging, brand recall will be created. A handcrafted design using printed parchment paper can convey the quality and attention to detail of the products. We can use subtle background patterns, which will not counter the brand personality. The placement of strategic brands has the benefit of maximum publicity and consumer impact.

Print Preparation

Custom printing parchment paper requires precision in the preparation of its files. The scans of 100+ dpi are a necessity. Proper color profiles would help against color onslaught. Using color profiles, the color shifts are avoided, hence producing a predictable result, which helps in eliminating unwanted surprises, etc. The bleed areas should be provided so as to eliminate white boundaries after cutting. PDF or TIFF are the preferred file formats of the printer’s equipment, or EPS. The complex designs are managed through file organization on layers. Effective communication in printing services gives a clear understanding of the expectations rn or how these services should be delivered to achieve perfect results. Preparation is the key to saving time and cutting down errors.

Quality Control

Running through a custom personalized parchment paper layout optimization is done through quality control in the last step. All the aspects show up the way they are supposed to because the proofs should be checked before mass production. Check the place alignment, color precision, and sharpness. Physical samples are used to point out any custom printed sandwich paper that would not be noticeable on the digital screen. Taking up issues on time helps to avoid the expense of reprints. Correlation quality ensures brand reputation and customer satisfaction. An optimized layout leads to a final product that is professional and good-looking.

Conclusion

And that is the optimization of layouts when it comes to a custom parchment paper; you should know the material, where to place what, and come up with clear branding. Very conspicuous are the color selection and typography that contribute immensely to the final product and readability. Print requires technical preparation so that errors can be avoided and one can attain sharp results. In order to ensure the final parchment paper is satisfactory, quality control is there. A proper layout is another way of adding charm to the product and supporting brand image. When these strategies are followed, the designs on parchment papers become effective and beautiful. This makes plain old paper a potent branding instrument.